Wood Cutting Tools: The Ultimate Guide

Do you want to know about wood cutting tools? Wood craftsmen use many types of wood cutting tools, and all of them serve different purposes. Some cutting tools are for making straight cuts, while some can make curves and even offer intricate cuts and angled cuts. Therefore, the tools are selected according to the project and the type of cutting required.

This post may contain affiliate links, I earn from qualifying purchases at no extra cost to you. Click here for my disclosure policy

In this article, we will share the top wood cutting tools and explain their usage and purpose. If you are a beginner and looking for a suitable tool for diy projects that involve woodcutting, this article will help you choose the tool according to your needs.

Shop any of these stores and I receive a small commission at no cost to you.

Wood Cutting Tools: The Ultimate Guide

What are wood cutting tools? What tool is used for cutting wood? What tools are best for cutting wood?

Table Saw

A table saw is a must-have for every wood craftsman. It is an essential machine or tool that helps you turn a large piece of wood into pieces.

For instance, if there is a large MDF sheet, you can get clean cuts in the desired-sized pieces using a table saw. It will hardly take a few minutes.

It is a suitable tool for making straight cuts. They are used for crosscuts and rip-cuts. You can use them for large sheets of wood and convert them into the desired size.

VEVOR Table Saw for Jobsite...Shop on Amazon

VEVOR Table Saw for Jobsite...Shop on Amazon SKIL 15 Amp 10 Inch Portabl...Shop on Amazon

SKIL 15 Amp 10 Inch Portabl...Shop on Amazon BOSCH 10 In. Worksite Table...Shop on Amazon

BOSCH 10 In. Worksite Table...Shop on Amazon DEWALT (DWE7491RS) 10-Inch ...Shop on Amazon

DEWALT (DWE7491RS) 10-Inch ...Shop on Amazon

Further Reading

Laser Cutting Machine

A laser cutting machine is an advanced tool for cutting wood. The powerful laser beams burn the wood and remove the material from the surface. There is no physical contact with the material; only the heat of the laser beams does the job. They cut wood like a hot knife on butter.

The main use of a laser machine is to cut intricate wood carving designs, which is not possible through any other wood-cutting tool. You can cut any type of vector file or art, such as Mandala art, wall separators, wall clocks, etc. It is possible to cut wood in any shape and design and join multiple pieces together to create something exceptional.

These machines are used to make various types of products, such as home décor pieces, toys, wall art pieces, organizers, boxes, lamps, jewelry items, and uncountable things. It is used in industries as well as small business owners to cut the desired design.

The precision and speed of these machines are unmatched. They consider the fine details and cut small pieces with utmost perfection. The best thing is that these machines are automated. You only have to upload the design, and the machine will do the rest. They offer incredible speed of cutting, which depends on the machine’s optical power and other specifications.

Laser machines can cut plywood, hardwood, softwood, engineered wood, etc. They can cut various thicknesses according to the power of the laser machine. However, they are not for cutting thick wood pieces. Even if they can cut, they will take more time and straight cuts can be easily made using a saw.

The most important thing about laser machines is safety. These are very safe compared to other wood-cutting tools. They require minimal involvement of the operator, which reduces the risks. Secondly, there are various safety features in the machine.

xTool D1 Pro Laser Engraver...Shop on Amazon

xTool D1 Pro Laser Engraver...Shop on Amazon

Chainsaw

A chain saw is a mighty tool that is specially used to cut trees, large limbs, thick logs, and pieces of wood. It turns them into the desired size and shape.

It is difficult to cut thick wood logs using common saws, but chainsaws are the experts. Due to their handheld design and sharp running blade, they can go deep and cut wood in no time.

This is used to cut firewood, wood logs, furniture wood, and remove dead/damaged trees or tree limbs.

Husqvarna 120 Gas Powered C...Shop on Amazon

Husqvarna 120 Gas Powered C...Shop on Amazon Husqvarna 460 Rancher Gas P...Shop on Amazon

Husqvarna 460 Rancher Gas P...Shop on Amazon CRAFTSMAN Electric Chainsaw...Shop on Amazon

CRAFTSMAN Electric Chainsaw...Shop on Amazon BLACK+DECKER 20V MAX Cordle...Shop on Amazon

BLACK+DECKER 20V MAX Cordle...Shop on Amazon

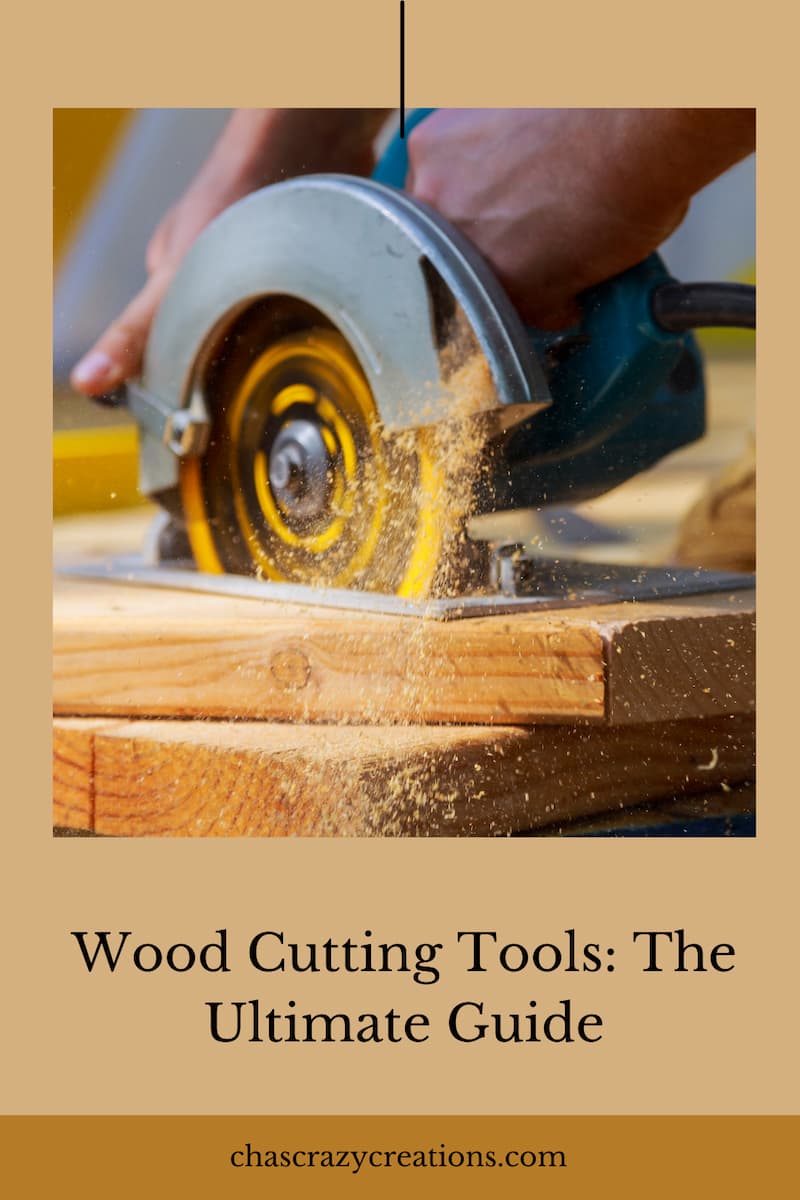

Circular Saw

A circular saw is a handheld saw that is an affordable option to make straight cuts. They can cut through the wood and turn large wood sheets into small pieces.

It is similar to a table saw but does not have a table. It uses the same blade and helps in making cross and rip cuts. The only difference is that it is handheld, which limits its usage.

Skil 5080-01 13-Amp 7-1/4" ...Shop on Amazon

Skil 5080-01 13-Amp 7-1/4" ...Shop on Amazon DEWALT Circular Saw, 7-1/4 ...Shop on Amazon

DEWALT Circular Saw, 7-1/4 ...Shop on Amazon DEWALT 20V MAX 7-1/4-Inch C...Shop on Amazon

DEWALT 20V MAX 7-1/4-Inch C...Shop on Amazon DEWALT 7-1/4-Inch Circular ...Shop on Amazon

DEWALT 7-1/4-Inch Circular ...Shop on Amazon BLACK+DECKER 20V MAX POWERC...Shop on Amazon

BLACK+DECKER 20V MAX POWERC...Shop on Amazon

Further Reading

Plane

When you want to flatten a piece of wood, improve its finish, or reduce its thickness, you need a plane. It makes the piece of wood smooth and even. It is similar to shaving wood and removing thin layers through a sharp blade.

You will find hand planes, as well as power planes, but hand planes require too much force. These are a must-have to give the final fishing to the piece of wood.

Taytools 469607 Jack Smooth...Shop on Amazon

Taytools 469607 Jack Smooth...Shop on Amazon GreatNeck C4 Bench Jack Pla...Shop on Amazon

GreatNeck C4 Bench Jack Pla...Shop on Amazon YOGEON Hand planer, Wood Pl...Shop on Amazon

YOGEON Hand planer, Wood Pl...Shop on Amazon Taytools 469614 Smoothing B...Shop on Amazon

Taytools 469614 Smoothing B...Shop on Amazon

Router

A wood router is a special tool for cutting wooden sheets. It is not used to cut wood sheets into small pieces. Instead, it helps in making cutouts in the center of the wood and duplicating a pattern. There is a rotating blade that helps in shaping, trimming, and finishing wood. It makes perfect edges, which makes an object more beautiful.

For making different types of joints in wood, it is an ideal tool. For joining wood pieces, the joints are usually made using a router. If you want to create hollow space on the wood, it can be done by adjusting the blade of the router. It looks like a deep engraving.

Many wood craftsmen use routers for duplicating a design. They place stencils or draw the design on the wood and then trace it using the router.

BOSCH PR20EVS Router Tool, ...Shop on Amazon

BOSCH PR20EVS Router Tool, ...Shop on Amazon DEWALT Router, Fixed Base, ...Shop on Amazon

DEWALT Router, Fixed Base, ...Shop on Amazon SKIL RT1323-01 Router Table...Shop on Amazon

SKIL RT1323-01 Router Table...Shop on Amazon BOSCH 1617EVSPK Wood 12 Amp...Shop on Amazon

BOSCH 1617EVSPK Wood 12 Amp...Shop on Amazon AVID POWER 6.5 Amp 1.25 HP ...Shop on Amazon

AVID POWER 6.5 Amp 1.25 HP ...Shop on Amazon

Jigsaw

A jigsaw has a very unique design, due to which it can cut curved lines, circles, slots and various other shapes. It can also make straight cuts with perfection. The notable feature is that the cuts that you cannot make using a table saw or circular saw can be easily done using a jigsaw.

The reciprocating blade cuts wood sheets into the desired shape. However, the control of the machine depends on the operator.

Wood craftsmen draw the desired shape on the wood piece. They can also use a stencil. Then, the jigsaw is used to nail the job.

BLACK+DECKER Jig Saw, 4.5 -...Shop on Amazon

BLACK+DECKER Jig Saw, 4.5 -...Shop on Amazon DEWALT 20V MAX XR Jig Saw, ...Shop on Amazon

DEWALT 20V MAX XR Jig Saw, ...Shop on Amazon RYOBI ONE+ 18V Cordless Jig...Shop on Amazon

RYOBI ONE+ 18V Cordless Jig...Shop on Amazon SKIL 6 Amp Corded Jig Saw- ...Shop on Amazon

SKIL 6 Amp Corded Jig Saw- ...Shop on Amazon Makita XVJ03Z 18V LXT® Lit...Shop on Amazon

Makita XVJ03Z 18V LXT® Lit...Shop on Amazon

Miter Saw

Carpenters need a miter saw to make straight and angle cuts in a piece of wood. It has a dedicated table or base, and there is a rotating blade like a circular saw. The angle of the blade can be adjusted to get the desired cross-cut.

Miter saws offer incredible precision and accuracy. They cut wood molding and trim with perfection. But keep in mind that a miter saw is suitable for pieces having a small width. It can’t be used to cut large sheets.

Metabo HPT | Compound Miter...Shop on Amazon

Metabo HPT | Compound Miter...Shop on Amazon DEWALT 12-Inch Miter Saw, 1...Shop on Amazon

DEWALT 12-Inch Miter Saw, 1...Shop on Amazon Skil 10" Dual Bevel Sliding...Shop on Amazon

Skil 10" Dual Bevel Sliding...Shop on Amazon Evolution Power Tools R255S...Shop on Amazon

Evolution Power Tools R255S...Shop on Amazon

Reciprocating Saw

Reciprocating saws are quite useful for carpenters, especially those who renovate houses. The back-and-forth motion of the blade allows it to cut windows, flooring, walls, etc. It can also be used for pruning tree branches and cutting large wood sheets.

The notable feature of this saw is that it cuts through the wood even if there is minimal space. It is a handheld tool, which is why it is portable and lightweight. It is helpful for a wide range of tasks.

It is a handy tool that homeowners should also have to deal with common house problems and repairs.

DEWALT 20V MAX Reciprocatin...Shop on Amazon

DEWALT 20V MAX Reciprocatin...Shop on Amazon Skil 9206-02 7.5-Amp Variab...Shop on Amazon

Skil 9206-02 7.5-Amp Variab...Shop on Amazon DEWALT DCS387B 20-volt MAX ...Shop on Amazon

DEWALT DCS387B 20-volt MAX ...Shop on Amazon

Hand Saws and Traditional Craftsmanship:

At the heart of woodworking lies the time-honored hand saws. These manual tools, such as crosscut saws and rip saws, rely on the skill and physical prowess of the craftsman. The teeth of these saws are meticulously designed, with tooth count and tooth shape varying based on the desired cut. Cross-cut saws, for instance, possess fine teeth for smooth cuts across the wood grain, while rip saws have fewer teeth with a chisel-like edge to efficiently cut along the grain. The Japanese saw, known for its pull-cut design and exceptionally sharp teeth, showcases the artistry of hand tools that have been perfected over centuries.

Chisels, Axes, and Shaping Tools:

Beyond saws, chisels and axes play a pivotal role in shaping wood. Chisels with their sharp-edged blades are employed to carve intricate designs, create grooves, and achieve fine detailing in woodworking projects. Axes, on the other hand, are synonymous with raw power, effectively hewing large pieces of lumber or even felling trees. Their long blades and carefully balanced weight enable efficient and controlled cuts, a perfect marriage of craftsmanship and manpower.

Power Saws:

Blending Tradition with Technology: With the advent of technology, power saws have revolutionized woodworking. Electric power saws, powered by either rechargeable batteries or direct power sources, provide precision and efficiency that were previously unattainable with hand tools alone. The scroll saw, equipped with a fine, slender blade, enables intricate curves and detailed work. Meanwhile, the band saw utilizes a continuous band of teeth for smooth cutting, making it a staple in workshops for shaping irregular forms with utmost accuracy.

Specialized Tools and Niche Applications: Woodworking encompasses a wide range of applications, each demanding specific tools. Prune saws, tree loppers, and keyhole saws cater to outdoor tasks, allowing for precise cuts while dealing with branches, shrubs, and hard-to-reach areas. The coping saw, with its thin, flexible blade, is a go-to choice for intricate internal cuts and interior fretwork. Additionally, the lathe, an essential tool for woodturning, crafts symmetrical shapes by rotating a piece of lumber against a cutting tool, showcasing the fusion of innovation and tradition.

How can you cut wood without power tools?

Cutting wood without power tools requires relying on traditional hand tools and techniques. While power tools offer efficiency, manual tools have been used for centuries and can provide a more personal and connected woodworking experience. Here’s how you can cut wood without power tools:

- Hand Saws: Hand saws are versatile tools for cutting wood manually. Crosscut saws are used for cutting across the grain, while rip saws are used for cutting along the grain. Choose the appropriate saw based on your desired cut and use proper techniques to achieve clean and accurate results.

- Chisels: Chisels are essential for detailed woodworking, carving, and shaping. Use a mallet to drive the chisel’s sharp edge into the wood, carefully removing material to achieve the desired shape or cutout.

- Axes: Axes are useful for chopping, shaping, and roughing out wood. Use a chopping block to stabilize the wood and make controlled cuts. Different types of axes, like felling axes or hatchets, are suitable for various tasks.

- Hand Planes: Hand planes are used to smooth, flatten, and shape wood surfaces. They can be used to achieve even thickness, create chamfers, and refine edges.

- Coping Saws: Coping saws are great for making intricate cuts and curves in wood. They’re commonly used for detailed scrollwork and artistic designs.

- Drawknives: Drawknives have a sharp blade that’s pulled toward the user, making them effective for shaping and removing large amounts of wood quickly.

- Hand Drills and Braces: Hand drills and braces are manual drilling tools that can be used to make holes in wood for various purposes.

- Mallets and Chisels: Mallets are used in conjunction with chisels for carving and shaping. The mallet’s impact helps drive the chisel through the wood.

- Scribes and Marking Tools: Accurate measurements and markings are crucial in woodworking. Use scribes, marking gauges, and rulers to ensure precise cuts and joints.

- Saws and Sharpening Tools: Properly sharpened tools are essential for clean cuts. Learn how to sharpen your saws, chisels, and other cutting tools to maintain their effectiveness.

- Vices and Workbenches: Sturdy workbenches and vices provide a stable platform for cutting, shaping, and assembling wood.

- Safety Equipment: Always wear appropriate safety gear, including eye protection, ear protection, and work gloves, to ensure your safety while using hand tools.

- Patience and Practice: Working with hand tools requires practice and patience. Take your time, especially when starting, and gradually refine your skills to achieve better results.

Whether you’re creating intricate designs or constructing functional pieces, cutting wood without power tools offers a deeper connection to the woodworking process. It allows you to experience the tactile nature of the wood and gain a better understanding of how each cut shapes the final piece.

What is the most efficient way to cut wood?

Cutting wood without power tools involves using manual hand tools and traditional techniques. While power tools can expedite the process, hand tools provide a deeper connection to the craft and a more deliberate approach to woodworking. Here’s a step-by-step guide on how to cut wood without power tools:

- Gather Necessary Tools:

- Hand saws: Choose the appropriate type of saw based on the cut you need (crosscut saw for cuts across the grain, rip saw for cuts along the grain).

- Chisels: Select chisels of various sizes for shaping and carving.

- Mallet or hammer: Needed for driving chisels and other cutting tools.

- Measuring tools: Use rulers, squares, and marking gauges for accurate measurements and layout.

- Mark Your Cut:

- Measure and mark the wood where you intend to make the cut. Use a pencil, marking knife, or other marking tool to create a clear line.

- Secure the Wood:

- Use clamps or a vice to secure the wood firmly in place. This prevents movement during cutting and ensures safety.

- Choose the Right Saw:

- Depending on the cut you need, select the appropriate hand saw. For straight cuts, use a back-and-forth motion with the saw. Keep the blade perpendicular to the wood’s surface.

- Cutting with a Hand Saw:

- Position the saw blade on the marked line and start the cut by applying gentle pressure.

- Use the entire length of the saw’s blade for efficient cutting. Let the weight of the saw do most of the work; avoid pressing too hard.

- Using Chisels:

- For shaping and detailing, use chisels to remove wood in controlled increments.

- Place the chisel’s edge on the wood along the marked line and use a mallet or hammer to gently tap the chisel until it begins to cut.

- Gradually increase the force of your taps while guiding the chisel along the cut line.

- Coping Saws and Curves:

- Coping saws are ideal for cutting curves and intricate designs.

- Install the coping saw blade, thread it through a starter hole, and then guide the saw along the marked curve.

- Finishing Touches:

- After making the cut, use chisels, hand planes, and sandpaper to refine and smooth the cut edges.

- Safety Precautions:

- Wear safety glasses, hearing protection, and work gloves to protect yourself from wood chips and splinters.

- Practice and Patience:

- Cutting wood by hand requires practice to develop skill and precision. Be patient and take your time to achieve accurate cuts.

- Maintenance:

- Keep your hand tools sharp by regularly sharpening blades and edges.

- Enjoy the Process:

- Cutting wood by hand allows you to engage with the material and the craft on a deeper level. Embrace the tactile experience and the sense of accomplishment as you shape the wood with your own efforts.

Remember that cutting wood by hand may take more time than using power tools, but the results can be highly satisfying and rewarding. Over time, your skills will improve, and you’ll gain a greater appreciation for the art of woodworking.

Here is an article that might help: Choosing the Best Wood for Your Woodworking Projects

Wood Cutting Tools Final Words

These are the top wood-cutting tools designed for different tasks and purposes. You don’t need all of them; you can select a few of them according to the jobs you do and the purpose of the tools. It is wise to spend on power tools because these save a lot of time and make the job easier.